Presaturated wipes are used for a variety of general and critical tasks throughout manufacturing and maintenance processes. However, not all presaturated wipes are the same. They are manufactured from a wide variety of substrates, made with different manufacturing methods, and finished with different surface treatments to enhance particle pick-up or increase absorbency.

It’s important to select a wipe that meets the application requirements. However, a wide range of non woven wipes, microfiber wipes and polyester wipes, etc. are available on the market. How do you select the right wipe?

Choosing the right presaturated wipe

Depending on the wipes composition, its properties can suit very specific applications, or on the contrary be suitable for multiple, more general operations.

It’s important to understand the application requirements and select a wipe that not only has the properties to suit, but that also balances cost and efficiency. It’s not necessary or cost efficient to use a high specification wipe for a general cleaning operation, and vice versa.

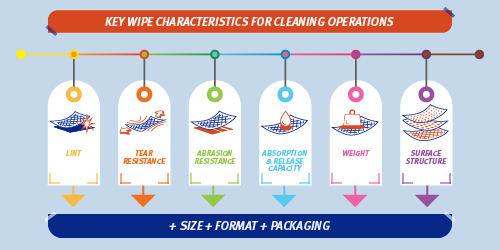

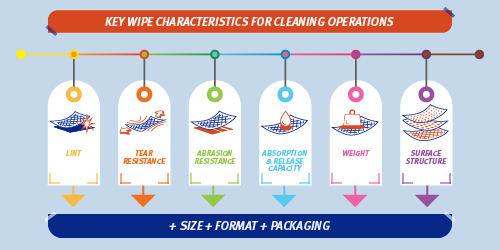

6 key wipe characteristics

Presaturated wipes differ in weight and size, level of cleanliness and impregnating options. The below are the key qualities to look for in surface cleaning and surface preparation operations. Make sure to look for these qualities prior to critical applications such as painting or bonding.

#1. Lint

Lint is the fibers released from the wipe which remain on the surface after the cleaning operation. This is an issue in surface cleaning operations as it can interfere with subsequent processes, or pose a FOD (Foreign Object Debris)* risk.

In critical cleaning operations (e.g. fuel tanks), FOD is a major concern. Premium quality 100% polyester knitted wipes should be considered here. The amount of particles released is so small they can almost be classified as lint free wipes.

In other, non-critical surface preparation operations it can still be necessary to control the amount of lint. Consider non-woven, low lint wipes for these operations.

Lint free wipes and low lint wipes are important for residue free surface cleaning.

#2. Tear Resistance

Tear resistance is another key characteristic. It indicates the wipes ability to resist tearing when exposed to mechanical stress and sharp edges during the cleaning process.

The best tear resistant wipes will be those manufactured from strong synthetic fabrics such as polyamide and polyester.

#3. Abrasion Resistance

The surface of an abrasion resistant wipe has the ability to resist wear. As a result, the wipe won’t fall apart when rubbed against / over abrasive or very abrasive surfaces such as rough composite during the cleaning process. Due to their construction and fiber strength, knitted or non-woven wipes with polyamide fibers are the best abrasion resistant wipes.

#4. Absorption & Release Capacity

Absorption and release capacity are two wipe characteristics that directly relate to the volume of solution available to clean the surface.

- The wipe material and composition have a direct effect on the absorption rate. They define the volume absorbed by the fibers, and also the volume absorbed into the interstitial spaces between the fibers.

- The release capacity is the percentage of impregnating solution released for cleaning during the wiping process.

In general, synthetic wipes have a good release capacity when used in conjunction with water based cleaners. For high absorption capacity, wipes made from natural fibers, such as 100% viscose wipes, are preferable. A mix of both is often used to balance cleaning efficiency and cost.

#5. Weight

The weight of the cloth is generally expressed in g/m² or g/ft². It is a characteristic affecting the absorption capacity as it controls the fiber content and the interstitial volume between fibers. For example, an 80g/m² cloth has a higher solvent capacity and is thus generally converted into large wipe sizes suitable for cleaning large surfaces areas (>1m²).

For more localized cleaning operations such as surface cleaning before bonding or sealing, a 50 g/m² wipe is more suitable. Its solvent capacity is such that it only contains the amount of solvent necessary for the task.

#6. Surface Structure

Embossed or aperture wipes are preferable for sealant removal and cleaning heavily contaminated surfaces. They are more efficient at picking up, retaining and removing sealant and other heavy contaminants such as grease and material chips.

Smooth structure or non abrasive cloth is better for delicate surfaces such as glass or painted surfaces to avoid scratches, abrasion and residual trace. A microfiber wipe is good at catching and holding soil and dust.

These are the 6 key characteristics to look at when choosing a presaturated wipe. However, they are not the only points to consider.

Wipe size, format and packaging

It is important to carefully consider the options available as they all impact on the final cost and how easy the pre-saturated wipe solution is to use.

Wipe Size

The size of the pre-saturated wipe should suit the cleaning application and the size of the surface to clean. For example:

- Using a large wipe to clean a small area or for a long cleaning operation will lead to excess solvent consumption through unnecessary waste and solvent evaporation. Large or extra-large wipes should only be used on large, unobstructed surfaces or on heavily contaminated surfaces.

- Using a small wipe on a large surface will increase the cleaning process cycle time and consume more wipes than is necessary.

Wipe size guide

The best practice is to use one wipe for one part (or defined surface area) to avoid cross contamination. The following is recommended:

- 15 x 15cm (6 x 6 inch) wipes for cleaning touch ups, excess sealant removal or localized surface preparation operations.

- 15 x 23cm to 20 x 30cm (6 x 9 inch to 8 x 12 inch) are the most common wipe sizes. They are used for surface preparation operations. The volume capacity is sufficient, and the dimensions are ‘hand sized’ to suit hand wiping applications.

- 30 x 30cm to 30 x 52cm (12 x 12 inch to 12 x 20 inch) is a good wipe size for large surface pre-paint wipes or inter-operation degreasing operations.

Wipe Format

The wipe size and quantity is essential. It’s also important to consider if the wipes will be roll wipes, or flat and stacked individually.

Roll wipes

The most economical way to convert cloth into wipes in large quantities, thanks to the quick cutting process. There can be as little as 50 wipes, or as many as 500 wipes, on a roll. The roll is perforated so the wipes can quickly and easily be separated. Large wipe sizes can be folded in two to reduce the height of the roll and the size of the packaging. Roll wipes are the most popular format when consumption is high.

Flat pack wipes

A flat pack is a stack of individual wipes, normally packed in quantities of less than 50 wipes. Wipes are half folded, ¼ folded or Z folded.

It is used in packaging that contains a lower quantity of wipes helping to reduce its over-consumption. It is also found in operations or areas where only a small quantity of wipes is necessary for the task, such as re-works or touch-ups.

The wipes in a flat pack are already separated. They are useful in critical operations that require zero fibres as there are no wipe separation fibres released.

Wipe Packaging

Packaging is particularly important for the end user. The right packaging can improve working conditions, logistics and storage on site, and reduce excess consumption and waste. Packaging can be divided into two categories:

Ready to use packaging

The packaging is part of the finished product. The benefit of this packaging is that it simplifies the supply chain. There is only one reference to manage, no reverse logistics (packaging to return). It eliminates the risk of cross contamination, e.g. putting solvent wipes into packaging that contained water based cleaners.

Ready to use packaging can be used with:

- roll wipes, in large quantities or wipe sizes. They are typically called “bucket wipes” in this format. They are particularly suited for outdoor operations, such as cable jointing in the Energy industry.

- flat packed wipes, in small quantities. Flat packs are suitable for use in vending machines. They help to control and monitor stock usage. The packaging size means they are good for applications in confined areas, or for touch-ups in hard to access areas.

Refillable and reusable packaging

Canisters and buckets that can be refilled with presaturated wipes supplied in pouches. They can be reused, reducing waste and environmental impact. The first step is to supply the quantity of packaging needed for the work stations.

- Canisters contain a medium quantity of wipes and are for use by a single person.

- Buckets contain a larger quantity of wipes. They are kept in a central position and used by several people.

Both solutions are easy to use, thanks to the improved packaging which is easy to open, stable and the right size for the wipes.

Conclusion

SOCOMORE has a wide range of approved aerospace wipes and industrial wipes, available presaturated with a large selection of solvent cleaners and water-based cleaners. Please download our presaturated wipes brochure, or contact us, for more information.

* In aviation, Foreign Object Debris (FOD) is any article or substance, alien to an aircraft or system, which could potentially cause damage.

Read more

[Article] Reducing VOC emissions in the aerospace industry

[Article] How can we limit VOC emissions in traditional industrial businesses?