Are you looking for a chrome VI free passivation solution for cadmium plated steel? SOCOSURF TCS/SCOP, from SOCOMORE, is a Cr(III) based alternative process to Cr(VI) passivation for cadmium plated steel.

SOCOSURF TCS/SCOP is qualified by AIRBUS to AIPI 02-04-013 since April 15th, 2019.

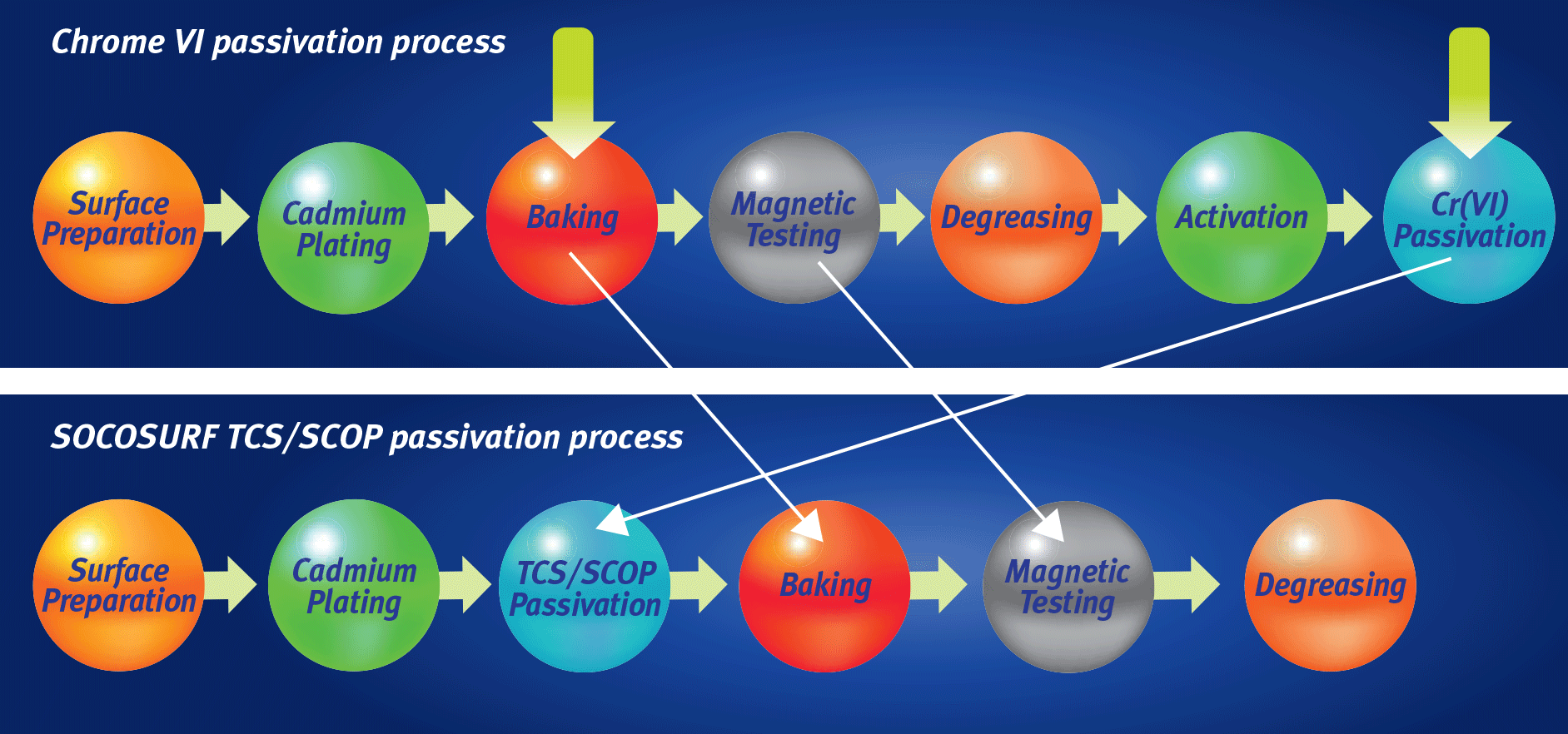

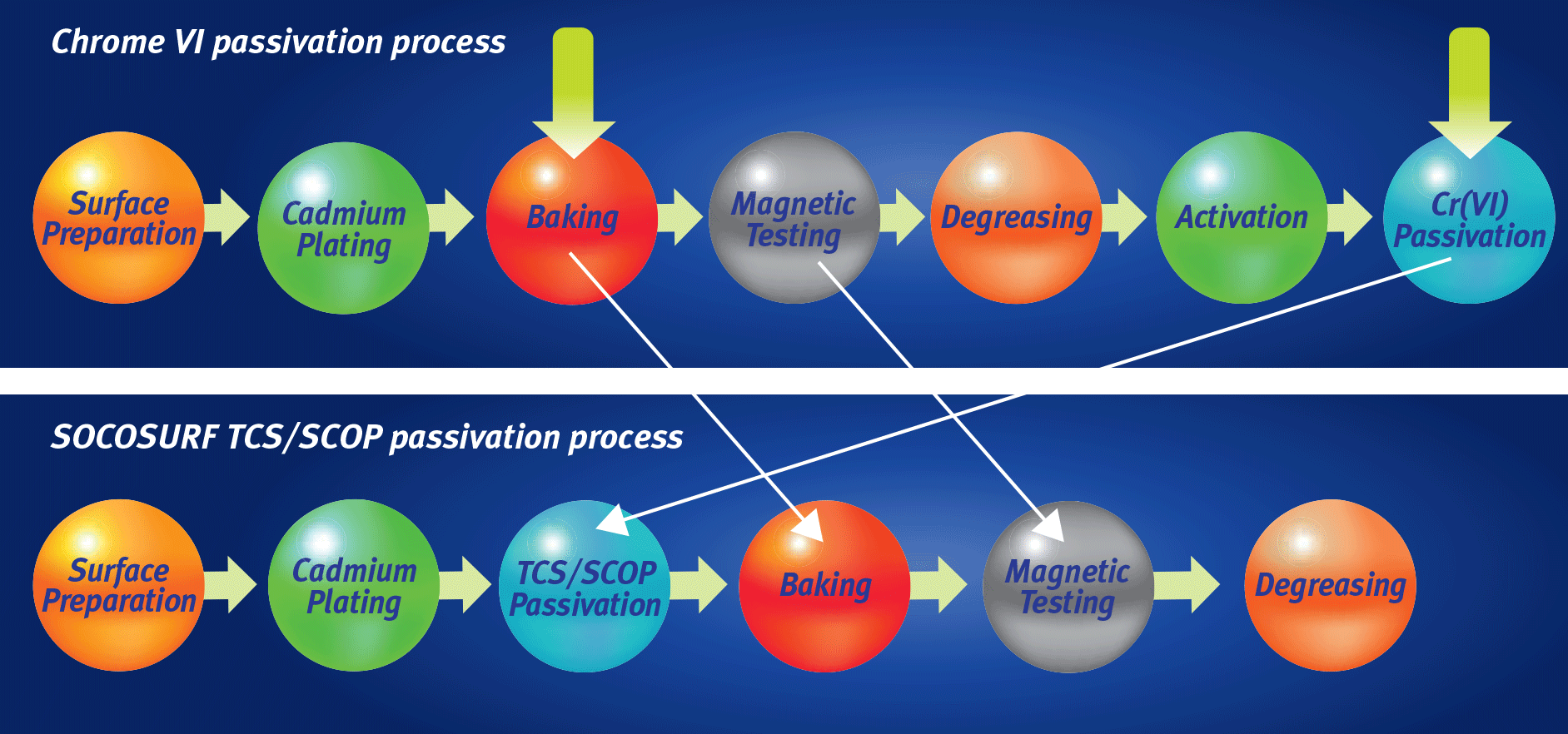

The traditional cadmium plating process has several stages: electrolytic deposition of cadmium, hydrogen de-embrittlement, non-destructive testing and chromium VI passivation.

It is mainly used in aerospace applications where cadmium plating is still used on steel parts such as landing gear, rivets and flaps.

What is SOCOSURF TCS/SCOP?

SOCOSURF TCS /SCOP is a one bath process that can be used in existing surface treatment lines as a direct hexavalent chromium replacement. It is a bi-component solution specifically developed to passivate and color cadmium plated steel.

- First component: SOCOSURF TCS is a trivalent chromium based alternative to the current Cr(VI) passivation solution.

- Second component: SOCOSURF SCOP enhances the corrosion resistance and colors the layer.

SOCOSURF TCS/SCOP is designed to replace Chrome VI passivation on cadmium plated steel.

Process Performance

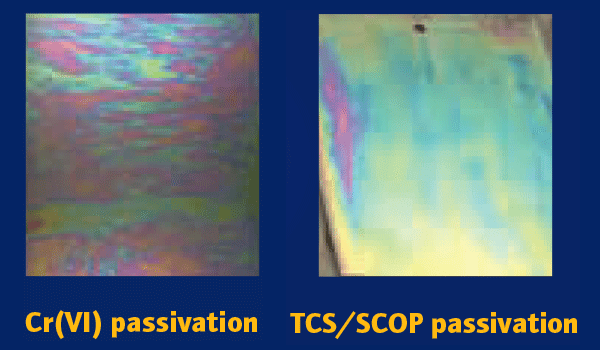

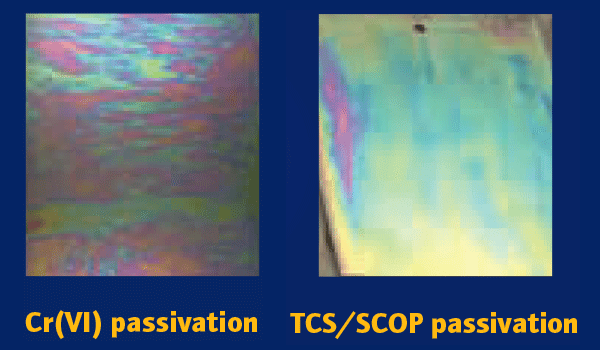

- Appearance: colored passivation layer.

- Corrosion resistance: no white corrosion after 96H SST (Salt Spray Test) and no red corrosion after 750H SST on cadmium plated steel.

- Paint adhesion: grade 0 (dry adhesion).

What are the benefits of SOCOSURF TCS/SCOP?

Environmental and safety improvements

SOCOSURF TCS/SCOP does not contain chrome VI or harmful substances.

“The operator can now use a Chrome VI free solution with very limited hazards. SOCOSURF TCS/SCOP is a REACh compliant solution.” explains Martin Goibier.

High temperature resistance and process optimization

SOCOSURF TCS/SCOP is heat resistant up to 200°C, which is higher than a chrome VI passivation solution. This is a great improvement for users as the passivation process is continuous.

There is no requirement to interrupt the process for dehydrogenation heat treatment, as it is required with the hexavalent chromium process, as baking occurs after passivation.

The benefits include:

- Less handling/manipulation of parts

- Process optimization: activation step is not required

- Time savings

- Reduced costs

Colored layer

The two-part SOCOSURF TCS/SCOP passivates and colors cadmium plated steel, resulting in visible coverage on the treated part. In comparison with other chrome VI free passivation solutions, after passivation the parts will be in color. This coloration helps the user to easily check if the whole part was successfully passivated.

Easier monitoring

SOCOSURF TCS/SCOP is a single bath, bi-component solution. Each component is controllable and adjustable. The bath lasts longer and the cost, process and performance can be easily monitored.