Energy saving and cost reduction are top priorities in today's discussions, with companies aiming to limit their environmental impact. The aerospace industry faces a major challenge in reducing energy consumption in its paintshops, where a specific warm temperature is required for efficient paint removal. As an alternative to other strippers, SOCOMORE has tested the efficiency of using its gel paint strippers at low temperatures. The goal is to provide paintshops with cost-effective solutions.

Energy consumption in the aerospace sector

Energy and cost-saving considerations

Energy-saving purposes

Industries need to adopt measures that help them save energy and costs, for many purposes:

- comply with regulations

- promote sustainability

- enhance their brand reputation

- ensure energy security and stability

Energy-saving benefits

By implementing measures to save energy, businesses can gain the following benefits:

- Cost savings

- Carbon emissions reduction

- A better image

- Increased resilience

Our expertise in aircraft surface preparation has taught us that aerospace paintshops, in particular, are actively looking for ways to reduce their energy consumption and costs.

Focus on paintshops heating systems

As a paintshop needs a heating system, its main worry is the energy used and the costs that come with it. Indeed, a consistent source of warm air is needed to guarantee the paintstrippers work effectively, generally between 20 to 30°C. This is the role of its heating system that, as you can imagine, uses a lot of energy ! This is especially the case if the heating system is not effective or if the paintshop represents a large space.

Reducing energy consumption in paintshops

For the paintshop industry, it is important to address this issue: reducing the energy consumption of paintshops’ heating systems.

To save energy in paintshop, many possible have been considered such as:

- using more stable and efficient paintstripper

- installing more efficient heating systems

- optimizing the use of heating systems

- improving insulation

These measures can help companies to reduce their energy expenses and improve their sustainable development practices.

Paint stripping at low temperature, a possible solution?

Why remove paint at low temperature?

As said previously, a paint stripper that is still efficient at low temperatures could reduce the energy consumption of a paintshop and the cost of operation. In the end, this can lead to notable cost reductions for paintshops, especially at larger-scale.

In summary, opting for a paint stripper efficient even at lower temperatures can bring the following benefits:

- decreased energy consumption

- cost savings

- enhanced worker safety

- reduced environmental impact

Possible application of paint stripping low temperature

Testing the efficiency of paint strippers usable at low temperatures has immediate applications. It can help businesses determine which paint stripping solution is most effective and efficient for their operations.

Companies can identify the lowest temperature needed for effective stripping. And do a first step in the optimization of energy consumption and the reduction of operational costs.

Which paint strippers for this test at low temperature?

For the test, we chose two paint strippers of our own gel paint stripper range.

SOCOSTRIP A0103N

SOCOSTRIP A0103N is a paint stripper for aircraft parts with hydrogen peroxide activation. It is free of phenols, chlorine and Cr(VI). It efficiently removes all types of paint and enables to reduce the stripping time and the number of applications needed.

Its viscosity is adjusted to facilitate manual application or airless spraying and provide perfect coverage of all surfaces, even vertical or overhanging. It also benefits from controlled evaporation.

SOCOSTRIP A0212 SR

SOCOSTRIP A0212 SR is a gel paint stripper with acid activation for all types of paint, non-corrosive for most metallic materials. This acid-activated paint stripper is suitable for all paints, particularly for epoxies, polyurethanes and alkydurethanes.

It is non-corrosive for most metallic materials (steels, aluminium alloys, titanium, ...) except magnesium, high strength steel and cadmium plated steel.

Chemical paint stripping at low temperatures: test and result

Conducting the paint stripping test at low temperatures

Presentation of the paint systems

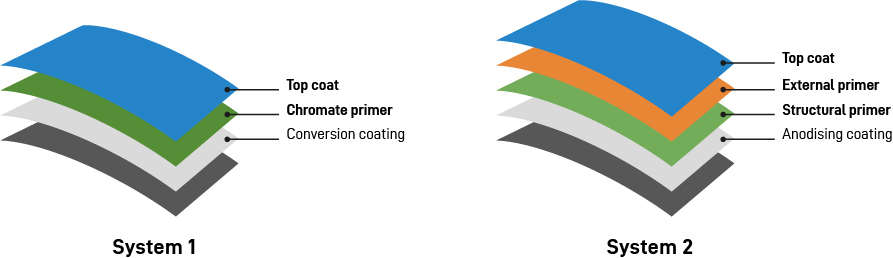

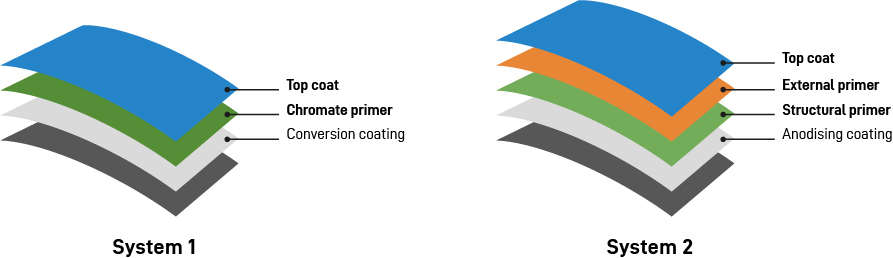

To see if our two paint strippers are also efficient at low temperatures, we conducted two efficiency tests on two paint systems.

- System 1: Conversion coating / Chromated primer / Top coat : two layers to remove

- System 2: Anodising / Structural primer / External primer / Top coat : three layers to remove

Surface to be paint stripped

The parts chosen for the paint stripping test come from a Boeing B727 retired aircraft, a common type of aircraft parts that are usually stripped in paintshops.

Surface to be paint stripped

The parts chosen for the paint stripping test come from a Boeing B727 retired aircraft, a common type of aircraft parts that are usually stripped in paintshops.

Tests series

Two sets of experiments were carried out to assess how the efficiency of our paint strippers is affected by temperature.

- The first series are performed in an unheated hangar, to reach a temperature between 8°C and 13°C. This is considered to be low temperatures for paint strippers, and temperatures we can commonly find in unheated paint shops.

- The second series of tests are performed in a heated hangar where temperatures are between 20°C and 25°C. Temperatures to normally apply our paint strippers.

Results of chemical paint stripping at low temperatures

Graphical results

|

SOCOSTRIP A0103N Peroxide activated paint stripper |

SOCOSTRIP A0212 SR Acid activated paint stripper |

|||||||

|

Application temperature |

8-13 °C |

20-25 °C |

8-13 °C |

20-25 °C |

||||

|

Contact time |

# applications |

Contact time |

# applications |

Contact time |

# applications |

Contact time |

# applications |

|

|

System 1 |

25 h |

2 |

16 h |

2 |

22 h |

2 |

14 h |

2 |

|

System 2 |

56 h |

4 |

24 h |

3 |

42 h |

3 |

16 h |

2 |

Results analyses for paint stripping at low temperatures test

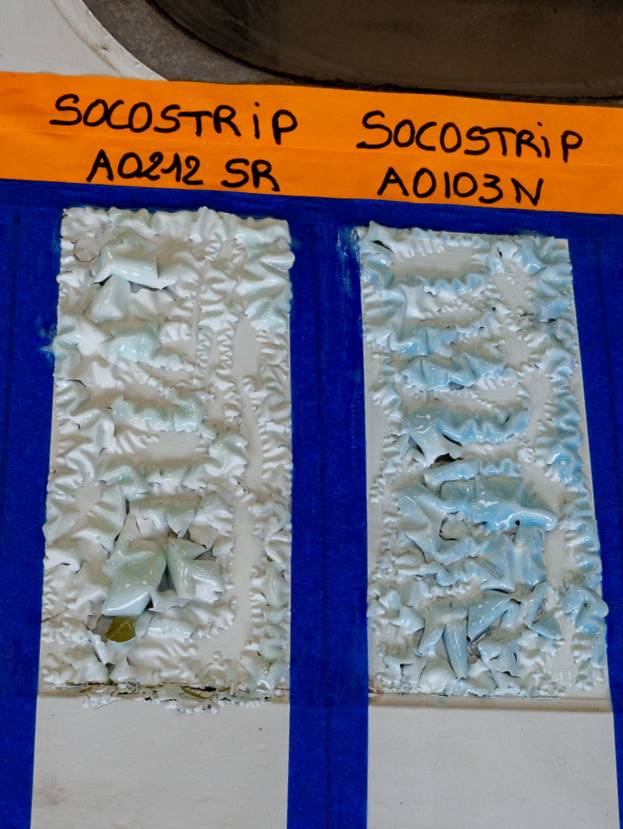

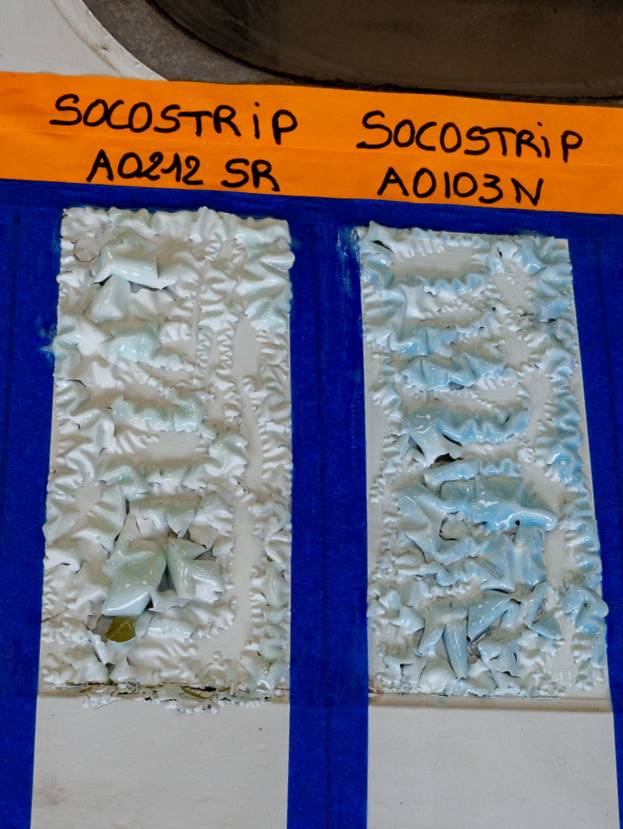

Despite very low temperatures (as said previously between 8-13 °C), both paint strippers were able to remove the paint systems.

Therefore, we can observe that at a low temperature, the acid-activated paint stripper (SOCOSTRIP A0212SR) is quicker to remove the paint system than the hydrogen peroxide-activated one (SOCOSTRIP A0103N), especially for the more resistant paint system

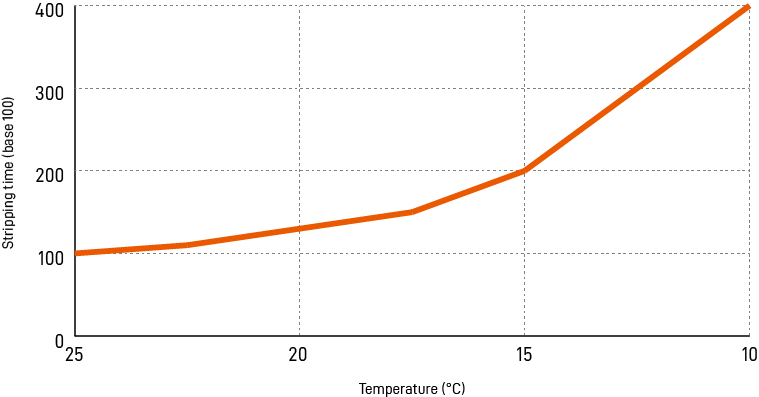

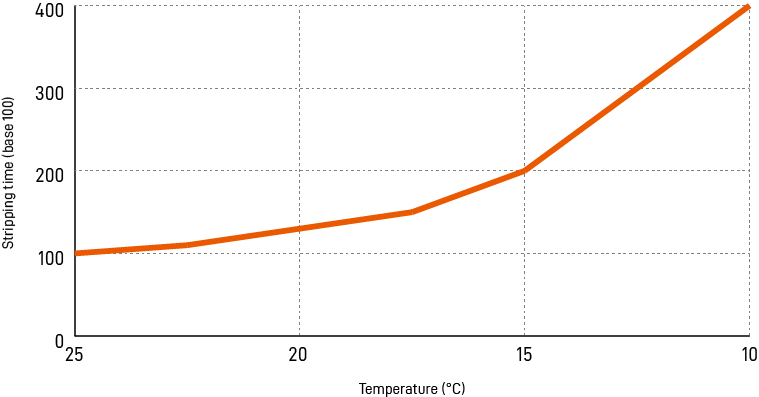

Compared to a standard stripping temperature (20-25 °C), the stripping time is increased from about:

- 15 hours to 20-25 hours for system 1

- 15-25 hours to 40-55 hours for system 2

This test demonstrates that it is possible to paintstrip at low temperatures, even at very low temperatures near 10 °C. This is a huge opportunity to reduce energy consumption and associated costs for the paintshop.

But we need to keep in mind that it implies a higher total stripping time and, in some cases, a higher consumption of strippers when more strippers application is needed. Anyway, most of the paint shops will certainly choose to lower the temperature of the paint shop by a few degrees, which will already allow significant energy savings without major impact on the stripping time by using these 2 strippers that have proven to be very efficient at low temperature.space paint stripping process.

Beyond the paint stripping at low temperature test

Our aircraft paint strippers performance

It is worth to mention that, in this test, even at low temperatures, SOCOSTRIP A0212 SR and SOCOSTRIP A0103N are more efficient than other strippers available on the market.

When the paint remains for a long time (10-15 hours) on the aircraft before being stripped, a successful stripping can be achieved thanks to these 2 key properties:

- a good anti-evaporation system: to keep the active substance without evaporation and to maintain a homogeneous wet gel product on the surface (no drying)

- a good rheology: to maintain a homogeneous thickness (>500µm) without run even on vertical surfaces for a long time.

Enhancing safety while lowering costs

In addition to being efficient at low temperatures, SOCOSTRIP A0103N and SOCOSTRIP A0212 SR allow to enhance safety in aerospace paintshops. Thanks for their slow evaporation rate which reduce the risk of fire hazards, ensuring the safety of workers and the environment.

As surface preparation experts, we are always available to answer any questions you may have about SOCOSTRIP A0103N and SOCOSTRIP A0212 SR at low temperature.

Contact us today to learn more and improve your aerospace paint stripping process.