SOCOSTRIP A0103N is a new generation gel paint stripper for epoxy and PU paint systems. It is used on all metals except for magnesium.

Activated by hydrogen peroxide, it removes all paints. It is particularly adapted for epoxy, polyurethane, and alkyd urethane paints.

Most of the time paint strippers contain dichloromethane, phenols, chromates, or acids. They are a risk for Health, Safety and the Environment. SOCOSTRIP A0103N is free from phenols, chlorine, and hexavalent chromium (Cr(VI)). It limits the HSE risks.

The solution is qualified by all major aircrafts OEM.

Main benefits of SOCOSTRIP A0103N paint removal for aircraft:

- Limits the risks for health, safety, and environment. It contains no phenol, chromates, methylene chloride

- Efficient as it provides strong stripping power quickly

- Particularly adapted for epoxy, polyurethane and alkyd urethane, and other paint systems

- Not corrosive and does not harm any aircraft metal parts, except magnesium alloy

- 8 months shelf-life from date of manufacture

Where can I use SOCOSTRIP A0103N thickened paint stripper?

SOCOSTRIP A0103N is a chemical paint stripper in a gel form. It is used on many parts of the aircraft exterior. The paint stripper is applied on:

- Fuselage

- Engine

- Aircraft equipment

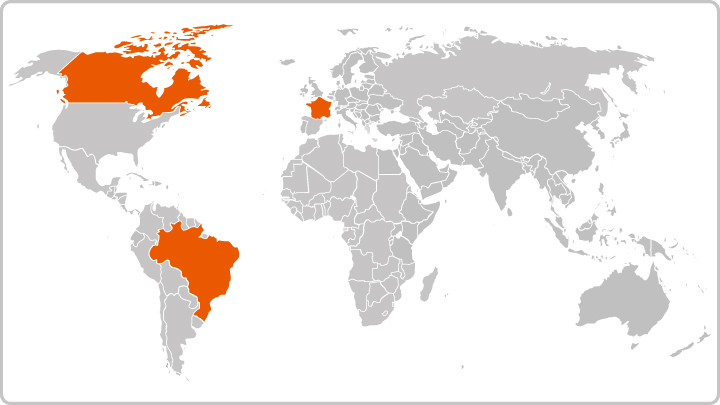

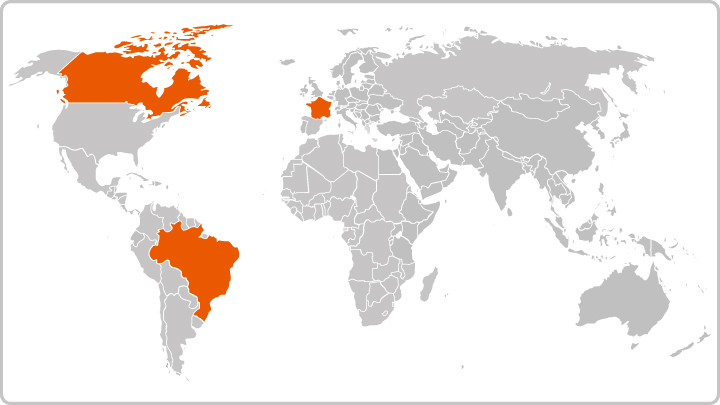

Convenient manufactured sites

Manufactured on 3 continents in France, Canada and Brazil, the paint stripper is easily produced and packaged. We serve our customers globally. Compared to paint strippers made in only one country, here are our deliveries benefits:

- Reduced haulage costs

- Shorter delivery / lead-times

Martin Goibier, Product Manager, states “We easily serve our European customers from our French production site. Our customers do not meet any supply issues due to BREXIT.”

What are the key factors for a good stripping?

Depending on their manufacturer guidelines, aircrafts must be repainted every 6 to 8 years. For a successful operation you need to take care of:

- Nature of the paint system temperature

- Surface preparation

- Thickness and homogeneity of the film

- Application methods

- Duration

Martin Goibier, Product Manager, says “ To ease the stripping application, make sure to properly prepare the surface to strip with a cleaning solution”.

SOCOMORE offers cleaners and degreasers such as SYNCLAIR A/C. It is a water-soluble concentrated cleaner for all metals suitable for use in bath or high pressure cleaner. SYNCLAIR A/C is the cleaner to use before and after the paint stripping application.

How to apply paint strippers on aircraft?

- At first clean and dry the surface with paint to strip. All soils and greases must be eliminated before the stripping operation. You can use a suitable cleaner from the SYNCLAIR, HYSO or DIESTONE ranges.

- Close and mask any openings and sensitive areas such as composites or polycarbonate parts.

- Apply the product manually, with a brush, or by low pressure spraying (airless) starting from the upper part of the aircraft or part to be treated. Paint strippers can be applied with various methods. Martin Goibier says “We recommend using spray guns to apply SCOSTRIP A0103N paint stripper, it gives better results than brushing”.

- Leave the stripper with the surface between 2 to 12 hours depending on the paint system, thickness, and/or temperature conditions. SOCOSTRIP A0103N does not dry and remains active during all that time.

- Scrap all the paint that is unstuck as well as the stripper residues. Re-apply a new coat if necessary until all the paint has been eliminated.

- Rinse the surface with pressurized water when all paint residues are removed. Adding SYNCLAIR A/C solution to the water will facilitate the cleaning operation.

- Clean the surface to re-paint with a solvent from our DIESTONE range for example.

Main qualifications

SOCOSTRIP A0103N is a multi-qualified paint stripper:

- AIRBUS,

- BOEING,

- DASSAULT,

- ATR,

- AIRBUS HELICOPTERS,

- EMBRAER,

- HAWKER BEECHCRAFT, etc.

See the full approval list here.

Aircraft paint stripping solutions range

SOCOMORE has a complete range of paint strippers. Other products in the range include:

- SPC-909N: a water-based hydrogen peroxide activated aircraft paint stripper.

- SOCOSTRIP A0212: an acid-activated gel paint stripper. It removes all paints.It is especially suited to epoxy, polyurethane, and alkyd urethane paints.

- SOCOSTRIP A0102N: an alkaline activated gel paint stripper. It is used for intermediate coats aircraft paint systems (for composite aircraft). It removes the upper and intermediate coat, leaving the primer intact.

- SOCOSTRIP A0109N: a new generation paint stripper activated by hydrogen peroxide, with a very long shelf life.